Once the cows have been milked, the milk is stored in the bulk cooling tank (a cooled storage tank) on the farm. The milk is collected from the farms every two days by the cooperative’s tanker, ready to be transported to the dairy.

Our cheese making know-how

From a few litres of milk, it is possible to make many different cheeses. Fresh, soft, pressed, … , there is something for everyone!

But then, how is cheese made?

Follow us, we explain everything here!

1Milk collection

2Arrival of whole milk

On arrival at the dairy, the milk is checked for quality and samples are taken for analysis.

If the quality of milk reaches our standards, it is unloaded and stored in a cooled tank. However, if the quality is unacceptable, the milk is isolated, identified, and will not be used to manufacture any product.

3Pasteurising the cream

The milk is then pasteurised (heated to between 72° and 75° for 10-15 seconds) to remove any microorganisms in the milk.

4Curdling the milk

To curdle milk, it is necessary to add lactic ferments and rennet to make the milk coagulate!

Lactic ferments are made of specifically selected bacteria, which transform lactose, the natural sugar in milk, into lactic acid, which contributes to the curdling process as well as to preserving cheese.

Did you know?

Depending on the quantity of the rennet added, or the length of the curdling stage, the cheese produced will be different.

5Slicing the curd

In order to remove the water in the curd and promote a better drain-off of whey, the curd is sliced and re-sliced into cubes of various sizes; the size od the cubes are dependent on the type of cheese we want to produce.

6Dripping/dewatering and moulding

The curd is then placed delicately into various perforated moulds (depending on what shape of cheese is required).

The curd must then be left so that the remainder of the whey continues to drip off and the grains amalgamate to form the cheese. To ensure that the cheese is well drained, the moulds are turned several times.

Did you know?

The more the cheese is dripped at this stage, the less water it will contain, and the longer it will keep.

7Salting

There are two ways to salt cheese:

– add salt to the paste or the surface of the cheese, before moulding; ( some cheese are rubbed with salt during the ripening stage)

– plunging the cheese into a bowl of salted water called brine, after moulding.

8Ripening

Making fromage frais doesn’t involve ripening!

However, for other types of cheese, ripening makes it possible to continue the maturation of the cheese, so that it develops its flavours and reaches its final texture.

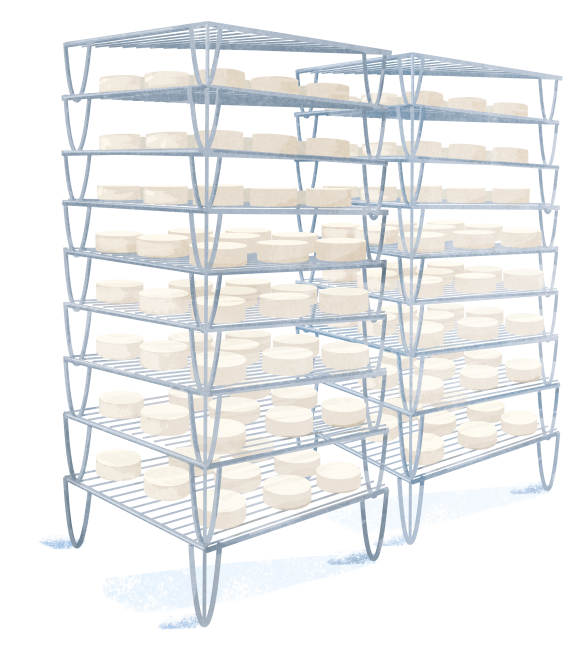

During ripening, cheeses are placed on racks and are turned by hand. They are placed in cold rooms or in ripening caves where the humidity, the temperature and the aeration are controlled.

To improve the ripening of the cheeses, fermenting may be carried out by placing specially selected moulds onto the surface of the products.

Did you know?

During the ripening stage, these moulds develop to form a fine crust on the surface of the cheese, which may be white, yellow, brown or bluish in colour. Ripening may last from a few days to several months. The longer the maturing period, the harder and drier the cheese will be and the more pronounced its taste will be.

9Packaging

The final stage is packaging the cheeses, not only to protect them, but also to allow the ripened cheese to continue maturing.

They are then put into boxes, then onto pallets and chilled before being sent to stores near you, ready for you to find in the deli area!

To go further ...

Discover our dairy cooperative

A french cooperativeOur Grand Fermage breeders promote the biodiversity!

Our CSR approach