Once the cows have been milked, the milk is stored in the bulk cooling tank (a cooled storage tank) on the farm. The milk is collected from the farms every two days by the cooperative’s tanker, ready to be transported to the dairy.

Our cream making know-how

The cream is also obtained by processing cow’s milk!

But how does it work in practice?

We explain everything here, from the collection of milk from our breeders to the packaging of our Grand Fermage creams.

1Milk collection

2Arrival of whole milk

On arrival at the dairy, the milk is checked for quality and samples are taken for analysis.

If the quality of milk reaches our standards, it is unloaded and stored in a cooled tank. However, if the quality is unacceptable, the milk is isolated, identified, and will not be used to manufacture any product.

3Skimming the milk

Using “centrifugation” to skim the milk makes it possible to separate the milk into two parts:

- skimmed milk

- and cream.

Milk heated to a temperature of 60° is continually squirted into a skimmer-centrifuge, which spins at a very high speed. This is how the cream comes out of the top centre of the skimmer and the skimmed milk comes out from the outside.

Did you know?

The name ‘cream’ is only given to the product which comes from skimming whole milk with a fat content of at least 30%.

The name ‘low fat cream’ is given to a product containing between 12% and 21% fat content.

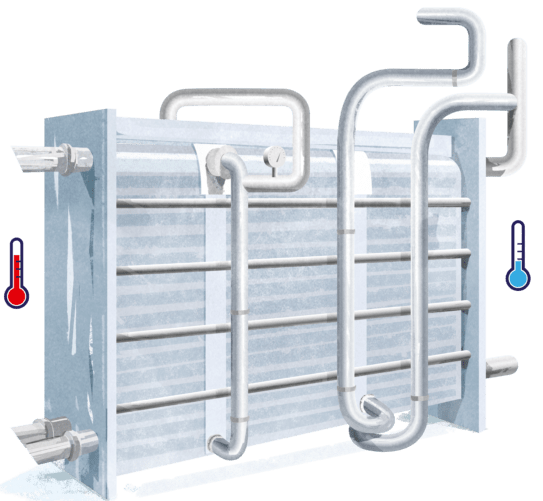

4Pasteurising the cream

The cream is then pasteurised (heated to between 65° and 95° for 20 seconds) to remove any microorganisms in the cream. Then it is cooled down again.

5Fermenting

Once the cream has been separated from the milk, it is in a naturally liquid state.

To make thick cream, the cream must be fermented. To do this, lactic ferments are added, and after these have matured, the cream has a thicker texture and a richer, more acidic taste.

6Packaging

The final stage is packaging our fresh creams.

Once it has reached a certain pH level, the cream may be packaged in our cream pots.

They are then put into boxes, then onto pallets and chilled before being sent all over the world, ready for you to find on the shelves of your local stores!

To go further ...

Discover our dairy cooperative

A french cooperativeOur Grand Fermage breeders promote the biodiversity!

Our CSR approach